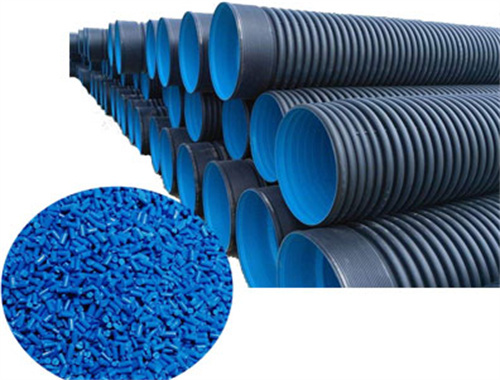

The full name of color master is color master, also called color. It is a new kind of special colorant for fiber materials. It consists of three basic premises: color paste or dye, carrier and additive. It is the aggregate obtained by symmetrically attaching excess color paste or dye to epoxy resin. It can be regarded as the molasses fermentation liquid of the color paste, so its coloring power is higher than the color paste itself. Color masterbatches are used in plastics to obtain the desired tonal effect in plastic or plastic pellet products.

The classification of color masterbatch is as follows:

Classification by carrier: PE masterbatch, PP masterbatch, ABS masterbatch, PVC masterbatch, EVA masterbatch and so on.

Classification according to the main use: such as injection master, injection master, spinning master, etc.

Classes can be classified into different levels, such as:

1. High grade injection molding masterbatch: Used for skin care packaging box, small toys, home appliance shell and other high grade products.

2. General injection color masterbatch: used for general daily plastic products, industrial production tools, etc.

3. High grade blown film color masterbatch: used for injection molding coloring of thin products.

4. General blown film color masterbatch: used for the injection molding coloring of general packaging bags and bags.

5. Spinning color masterbatch: used for dyeing textile chemical fiber spinning. The master material has fine particles, high concentration, good coloring power, high temperature resistance and light resistance.

6. Low-grade color masterbatch: used to manufacture low-grade goods with low color quality requirements, such as garbage cans, low-grade utensils, etc.

7. Special masterbatch: It is the masterbatch made of the same plastic as the carrier according to the type of plastic used in the product specified by the customer. For example, PP masterbatch and ABS masterbatch respectively take PP and ABS as the carrier.

8. Universal masterbatches: Some epoxies (usually PE with low melting point) also act as carriers, but can be used for coloring other epoxies in addition to their carrier epoxies. Universal master color is simple and convenient, but there are many defects. Customers are advised to use special masterbatch.

9. The high temperature resistance grade of special color masterbatch is generally consistent with the high temperature resistance grade of plastics used in the product. At room temperature, it can be used safely. Only when the following conditions will cause varying degrees of loss of color, one is the temperature exceeds all normal categories, one is the shutdown time is too long.

Post time: Aug-15-2022