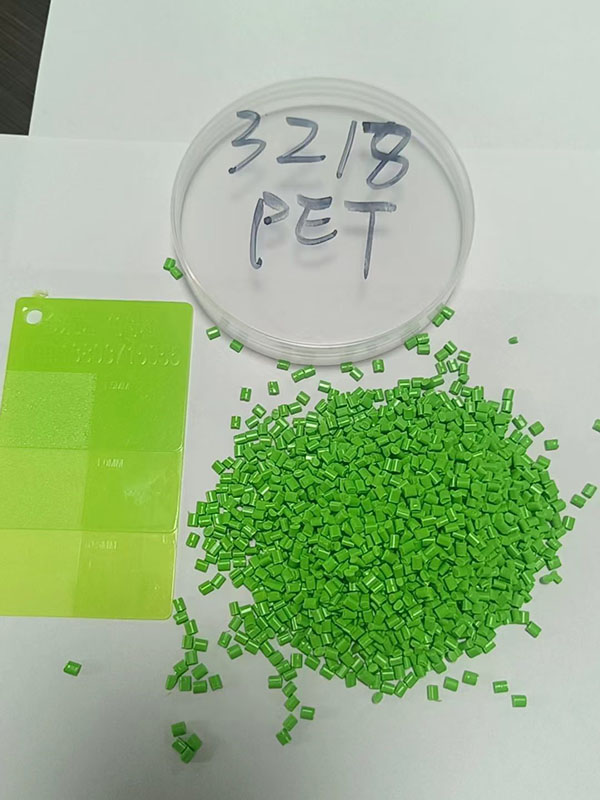

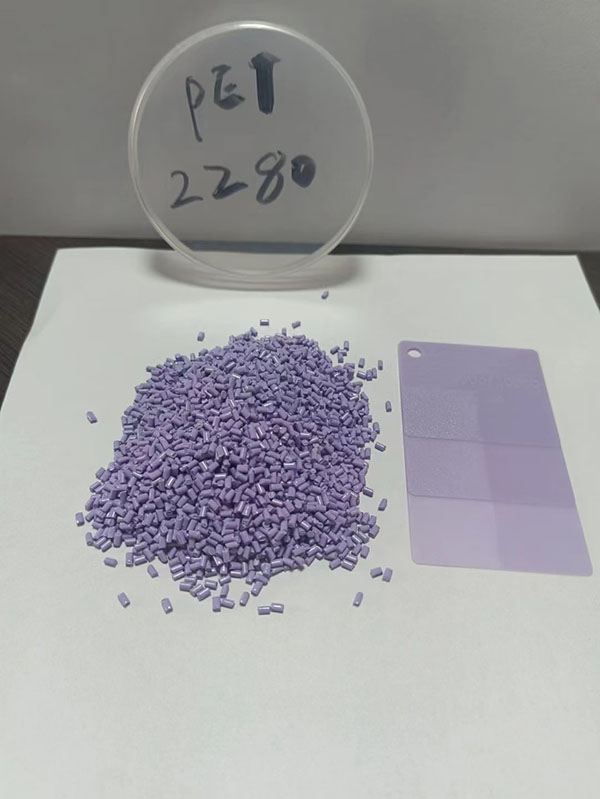

The full name of the color masterbatch is also called the color, is a new polymer material special colorant, it is composed of pigments or dyes, carriers and additives of three basic elements, is the super constant pigment or dye uniformly attached to the resin and obtained aggregate, can be seen as a pigment concentrate, so his coloring force is higher than the pigment itself. Masterbatches are mainly used on plastic. To achieve the desired color effect in plastic or rubber products.

Technical process method:

Color masterbatch production process requirements are very strict, generally using wet process. Color masterbatch is made by water phase grinding, phase transformation, washing, drying and granulation, only in this way can the quality of the product be guaranteed. In addition, while the pigment is grinding, a series of tests should also be carried out, such as measuring the fineness of the sand grinding slurry, measuring the diffusion property of the sand grinding slurry, measuring the solid content of the sand grinding slurry and measuring the fineness of the color paste.

Advantages of masterbatch:

1. Make the pigment have better dispersion in the product

In the process of color masterbatch production, the pigment must be refined to improve the dispersion and coloring power of the pigment. The carrier of the special color masterbatch is the same as the plastic variety of the product, and has good matching, and the pigment particles can be well dispersed in the product plastic after heating and melting.

2. It is beneficial to maintain the chemical stability of the pigment

If the pigment is used directly, due to the direct contact of the pigment with the air during storage and use, the pigment will absorb water, oxidation and other phenomena, and after the color is made, the quality of the pigment can be changed for a long time because the resin carrier will isolate the pigment from the air and water.

3. Ensure the stability of product color

The color master particle is similar to the resin particle, which is more convenient and accurate in measurement, will not adhere to the container when mixing, and the mixing with the resin is also more uniform, so it can ensure the stability of the added amount, so as to ensure the stability of the product color.

4. Protect the health of the operator

The pigment is generally powdered, easy to fly when added and mixed, and will affect the health of the operator after being inhaled by the human body.

5. Keep the environment clean and stain-free.

6. Simple process, easy to change color, save time and raw materials.

Post time: Jun-16-2023